"Focused on providing integral manufacturing services balanced with understanding and flexibility."

Capabilities

CNC Components has grown over the last decade by ensuring the staff, the equipment and the systems and processes they have in place are responsive to the needs of the marketplace, growing with clients and proactively investing in resources.

ISO Accreditation

The team here at CNC Components understands the importance of quality control and is committed to implementing ISO9000 in recognition of this.

Equipment

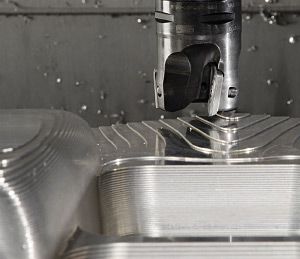

CNC Components invests heavily in the best equipment and the latest technologies to service clients’s needs. Current equipment includes:

CNC Milling

VFOE Vertical Machining Centre

X, Y, Z Travel 762mm x 406mm x 508mm

7500 Rpm, 20 tools, BT 40, 4th Axis

VF2SS Vertical Machining Centre

X, Y, Z Travel 762mm x 406mm x 508mm

12,000 Rpm Direct Drive 25 tools High Speed Changer

BT 40, 4th Axis

VF3D Vertical Machining Centre

X, Y, Z Travel 1016mm x 508mm x 635mm

10,000 Rpm 2 Speed Gear Box, 25 tools

BT 40, 4th Axis, probing/ first part inspection

VF3D Vertical Machining Centre

X, Y, Z Travel 1016mm x 508mm x 635mm

10,000 Rpm Direct Drive, 25 tools

BT 40, Through Spindle Coolant

4th Axis, probing/ first part inspection

VF5D Vertical Machining Centre

X, Y, Z Travel 1270mm x 660mm x 635mm

10,000 Rpm 2 Speed Gear Box, 30 tools

BT 50, Through Spindle Coolant

4th Axis

VF6 Vertical Machining Centre

X, Y, Z Travel 1626mm x 813mm x 762mm

7,500 Rpm 2 Speed Gear Box, 30 tools

BT 40, Through Spindle Coolant

4th Axis

Bridgeport Interact 2

X, Y, Z Travel 660mm x 305mm x 500mm

CNC Turning

SL30 Lathe

Swing 500mm dia x 800mm long, 78mm Bore

Parts catcher, programmable tail stock

3,400 rpm, 10 inch Kitagawa Hydraulic Chuck

Collet chuck to 3 inch Dia, 12 station Turret

Capto tooling

SL20 Lathe

Swing 275mm dia x 600mm long, 52mm Bore

Parts catcher, bar feeder, programmable tail stock

5,000 rpm, 8 inch Kitagawa Hydraulic Chuck

Collet chuck to 2 inch Dia, 12 station Turret

6 VDI, driven tools for C axis

Milling, drilling, both Radial and Axial 4500 rpm

6 standard tools

4 x SL20 Lathes

Swing 275mm dia x 600mm long, 52mm Bore

Parts catcher, bar feeder, programmable tail stock

5,000 rpm, Collet chuck to 2 inch Dia, 12 station Turret

6 VDI, 6 standard tools, Auto Probing

Grinding Surface

Okamoto SG63

X, Y, Z, 700mm x 350mm x 350mm

Auto-cycle Grind / Dress, spark out etc.

Jones and Shipman 1400

X, Y, Z, 600mm x 210mm x 200mm

Opti Dress, Auto-cycle Grind spark out etc.

Compound Sine Magnet, Radius dressers

Precision Vices etc.

Grinding / Cylindrical

Jones and Shipman 1212E

155mm Swing x 310mm long, centres

3 jaw chuck, 4 jaw chuck, 6 inch Magnetic Chuck

Internal/External, Universal Table

Jones and Shipman 1300EIU

310mm Swing x 610mm long, centres

3 jaw chuck, 4 jaw chuck, 8 inch Magnetic Chuck, Collet Chuck

Internal/External, Universal Table and Work Head

Double Wheel Head Universal

Cincinnati

260mm Swing x 710mm long, centres

Internal/External, Universal Table, Wheel Head and Work Head

Grinding / Spline / Tool

Jones and Shipman, tool and cutter grinder

Cincinnati, the Grinder being set up for spline grinding

All grinders have CBN and diamond wheels

Erosion

ARD, plunge EDM, 600mm x 400mm x 250mm tank

Brother, wire cut, 2D, 260mm x 160mm x 100mm

Fanuc Alpha, wire cut, 4 axis, 320mm x 220mm x 180mm

30 Machine Tools on the shop floor

Skilled Team

With the capabilities of the manufacturing industry increasing exponentially through the use of more and more sophisticated computer aided design packages and tools, so too has risen the requirement for businesses to invest in highly skilled and trained staff, and emerging technologies.

Realizing this trend, and due to its strong belief in high quality Australian manufacturing, CNC Components is constantly evaluating its performance and quality level. The strong and varied engineering knowledge of the team is crucial to developing clients’ projects.

By fostering a team of highly skilled designers, engineers and operators, CNC Components have been able to remain at the forefront and assist clients with increasingly complex needs.