Manufacturing

We take on large and small-scale manufacturing initiatives with precision and efficiency. At CNC Components, we are proud to be a Brisbane-based leader in CNC machining, offering expert precision and quality for a wide range of metal and plastic components. Our proven track record spans working with billets, castings, forgings, and fabrications, using the latest cutting tool technology to ensure that each component meets your exact specifications. Whether you need high-speed precision or large batch manufacturing, we provide fast turnaround times, cost-effective solutions, and unmatched precision across industries.

Capabilities

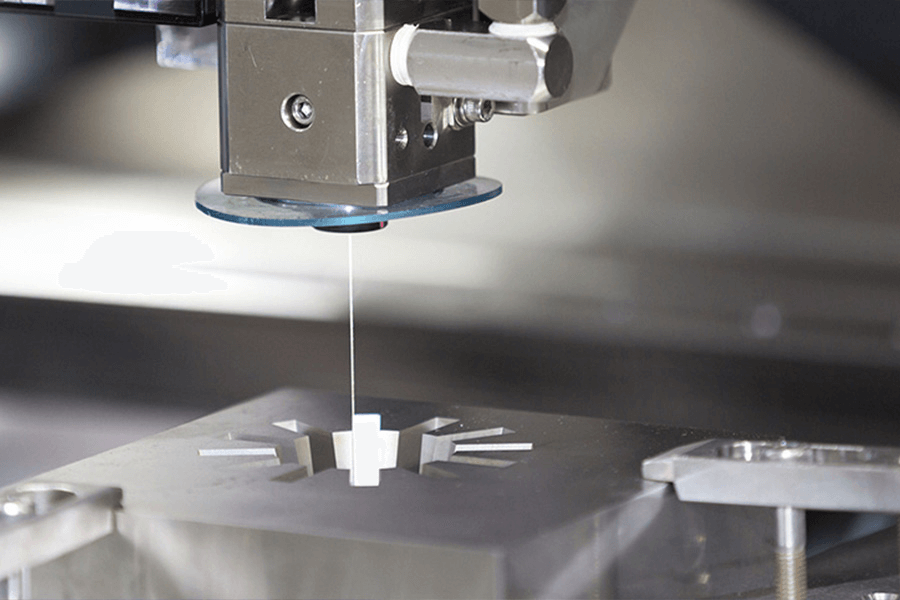

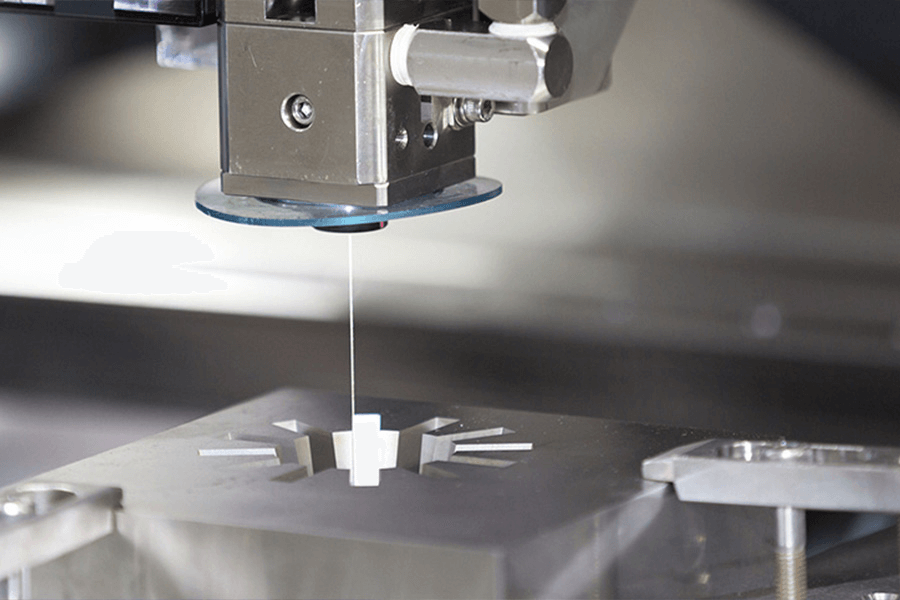

Wire EDM & Plunge EDM

Our Electrical Discharge Machining (EDM) and Wirecutting technology enable us to achieve extremely precise cuts with tolerances of +/- 0.005mm. It’s also capable of cutting through thick blocks of material up to 400mm in depth, with a high degree of accuracy on alloys like steel.

- Wire EDM: This technology allows us to create precise cuts in complex designs, ideal for intricate features that require fine detail.

- Plunge EDM: For creating sharp corners, deep ribs, concave shapes, and other detailed designs, plunge EDM provides efficient, high-quality results, particularly for dies, molds, and gear wheels.

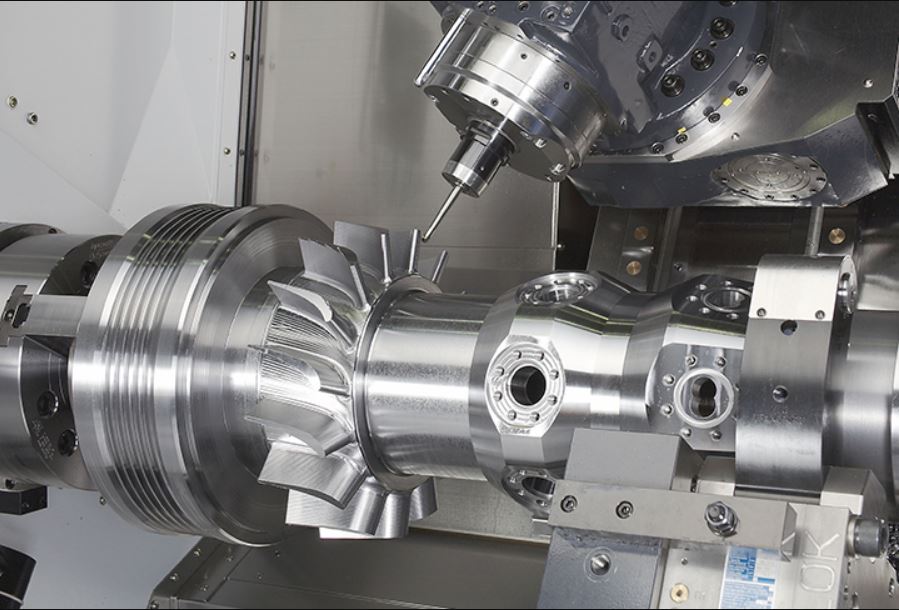

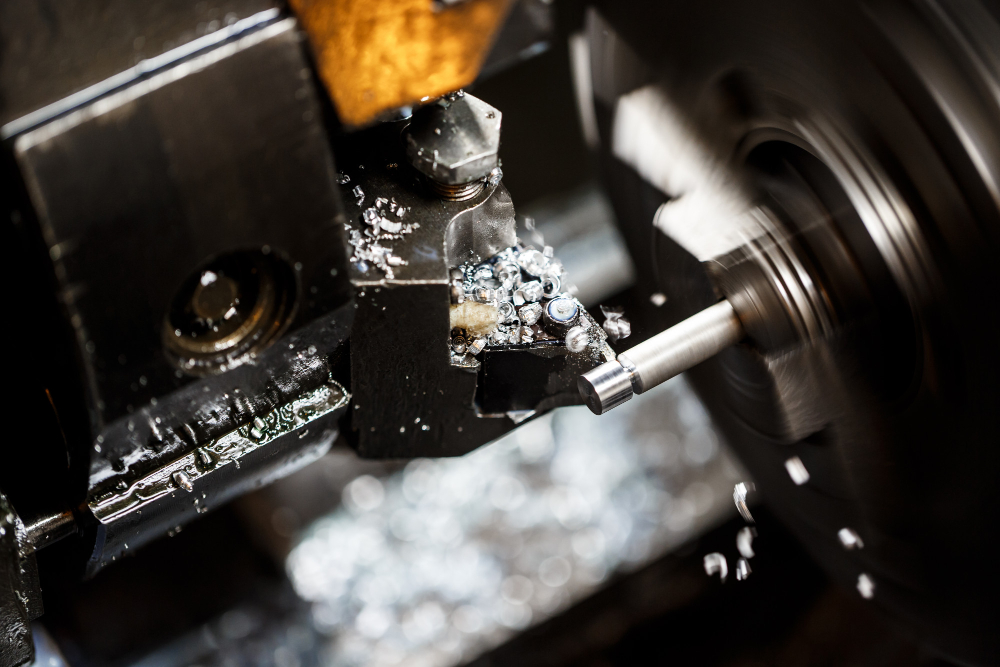

Milling & Turning

Our advanced CNC milling and turning processes shape raw materials into high-accuracy components for industries that demand perfection.

- CNC Milling: Using multi-axis machines, we cut, drill, and shape materials with pinpoint accuracy, perfect for complex geometries and tight tolerances.

- CNC Turning: Our precision lathes create cylindrical components with smooth finishes, ideal for shafts, bushings, and other rotational parts.

With state-of-the-art equipment and expert machinists, we deliver high-quality, consistent results—whether it’s a single prototype or large-scale production.

Cylindrical & Surface Grinding

Grinding is essential for achieving high precision, smooth finishes, and tight tolerances in machined parts. Our advanced grinding capabilities ensure flawless results for even the most demanding applications.

- Cylindrical Grinding: Ideal for round components like shafts and rollers, this process ensures precise diameters, smooth finishes, and exceptional accuracy.

- Surface Grinding: Perfect for flat surfaces, this method delivers uniform, ultra-smooth finishes with tight dimensional control.

With our expertise and high-performance grinding equipment, we guarantee precision, consistency, and superior quality in every component we produce.

CNC Machining Expertise

- Bearing Housings

- Bearing Retainers

- Couplings

- Duo Cones

- End Caps

- Hubs

- Impellors

- Tapered Pins

- And Beyond

- Sleeves

- Shafts

- Sheaves

- Spherical Housings

- Pistons

- Sleeves

- Spherical Housings

- Pistons

- Pins

- Special Bolts

- Steel Wheels

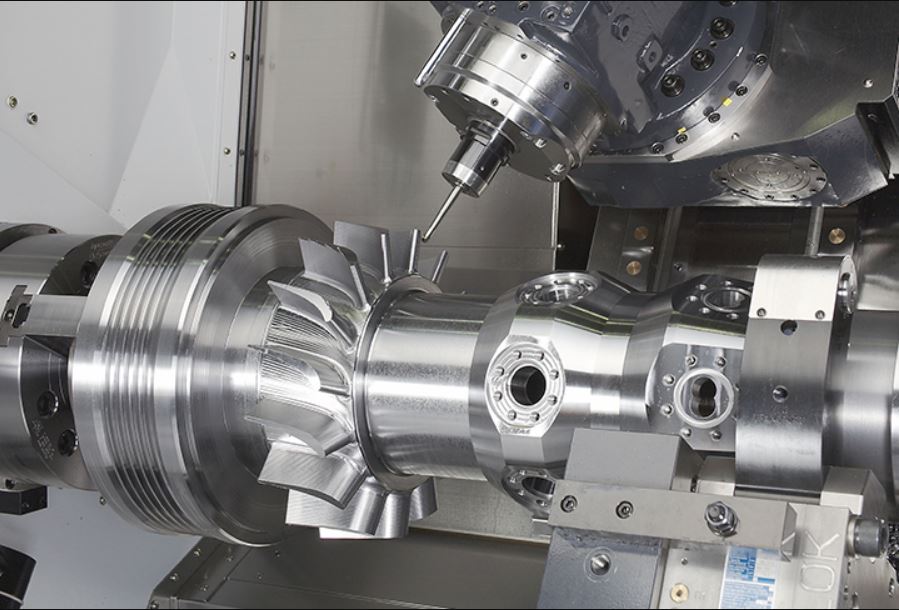

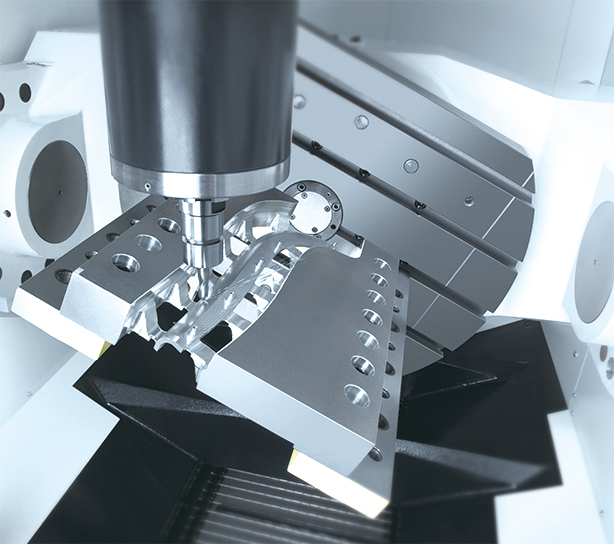

2D, 3D, 4D, 5D & 7D Axis Machining

One size doesn’t fit all. CNC Components works with multiple-axis machines to meet your specific requirements, giving you the most fit-for-purpose solutions with precision and efficiency.

3-Axis CNC Machining

Ideal for components where the workpiece stays stationary and the cutting tool moves along the XYZ plane. Common processes include milling slots, drilling holes, and cutting sharp edges.

5-Axis CNC Machining

5-axis machining allows for simultaneous movement in five directions. It’s perfect for creating detailed 3D structures, complex curves, and compound angled surfaces without relying on molding techniques.

7-Axis CNC Machining

Our 7-axis CNC machining is the cutting-edge of precision manufacturing. With seven axes of movement, including tool spinning, part rotation, tool head rotation, and clamping/reclamping, we can manufacture long, slim, and highly intricate components. The 7-axis machine improves post-fabrication processes and ensures precision in complex designs, cutting time and cost dramatically.